Products

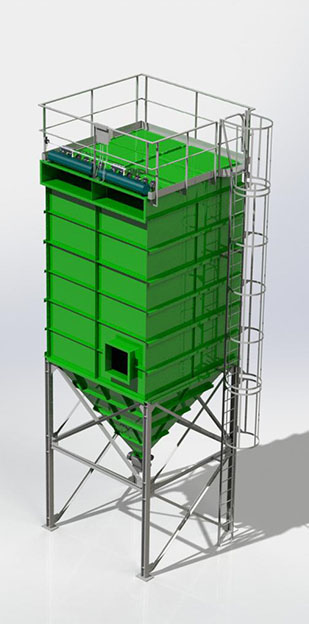

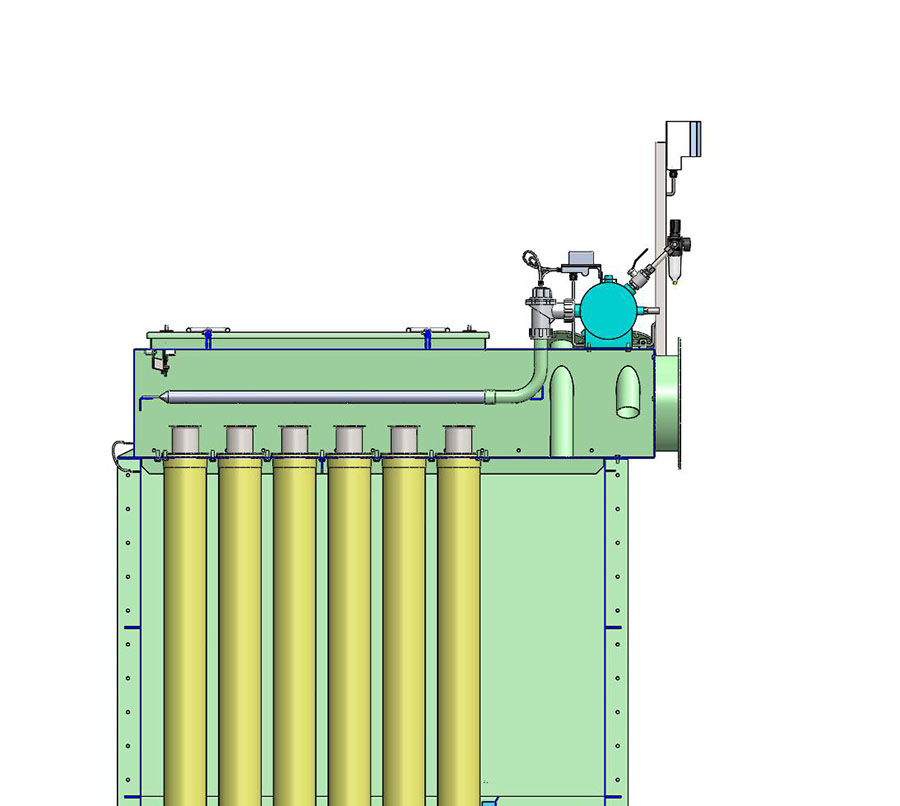

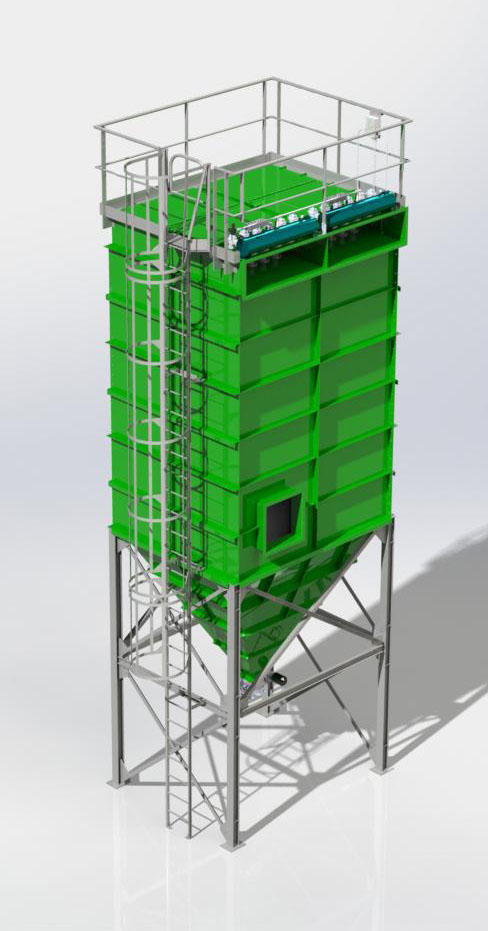

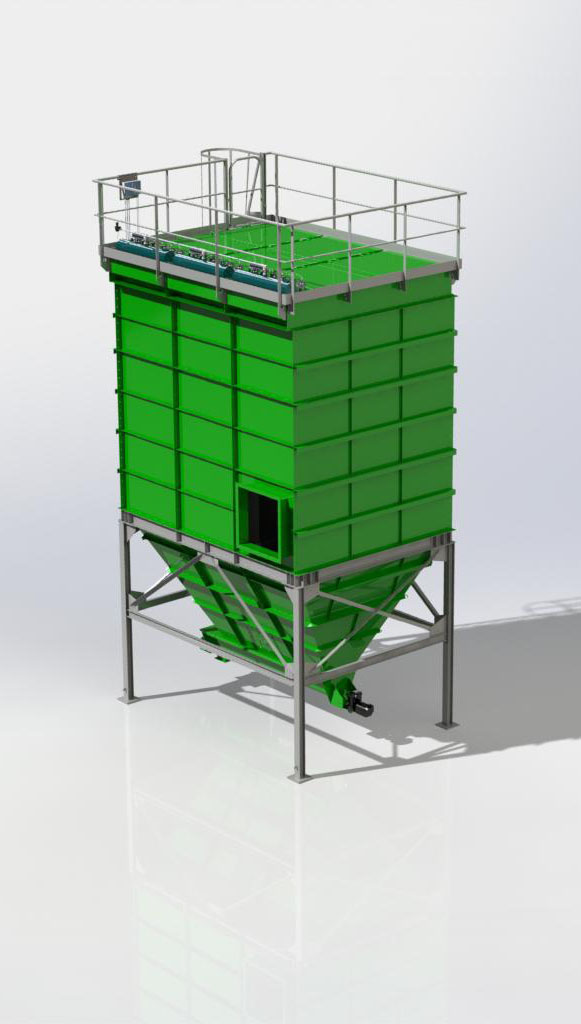

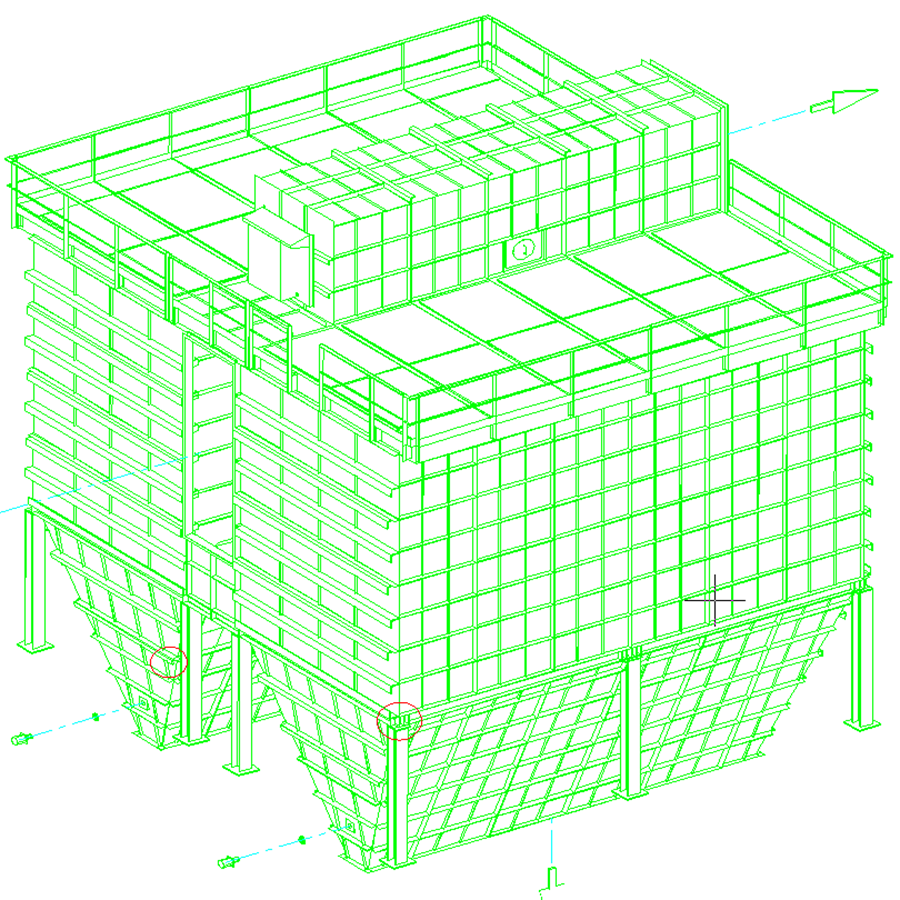

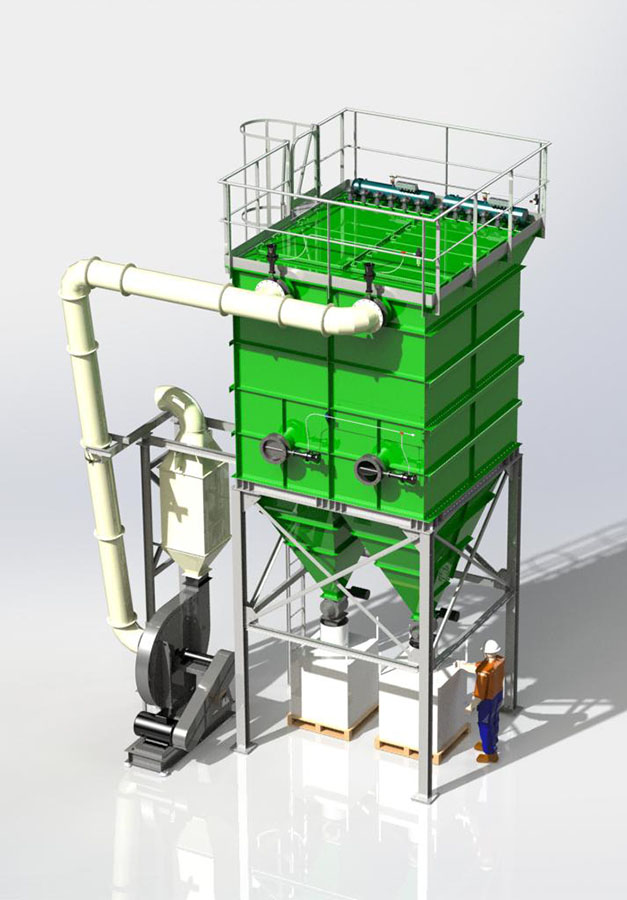

Baghouse dust collectorBaghouse dust collector FP type 10

Its function is to remove the dust contained in a gas.

Guarantees emission rates of less than 5 mg/Nm³.

Optimum cleaning efficiency for reduced compressed air consumption. Low maintenance costs (reduced spare parts requirement).

All our filter elements can be dismantled on the clean air side for easy maintenance and operator safety.

-Type 12 : clean air chamber

-Type 11 : clean air chamber + dirty air chamber

-Type 10 : clean air chamber + dirty air chamber + hopper

-Type 20 : double filter with clean air chamber + dirty air chamber + hopper

• Can process flows from 1 000 to 200 000 m³/h.

• Gamme standard résistant à une pression de - 5000 Pa.

• Standard range with pressure resistance of - 5000 Pa.

• Standard range with pressure resistance of - 10000 Pa

• Materials: painted steel, stainless steel (304L, 316L, 316Ti, Duplex, Uranus...), aluminum, polymer.

• Available in "silo top" version.

• Available in ATEX version.

• Available in high temperature version (up to 250°C continuous, peak at 280°C maximum).

• Available in off-line or semi-off-line versions.

• Available in circular version.

• Possibility of customized solutions according to customer specifications.

• Standard coating with customer color choice.

• Customized coating according to customer specifications

• Compressed air tanks according to ASME or GOST on request.

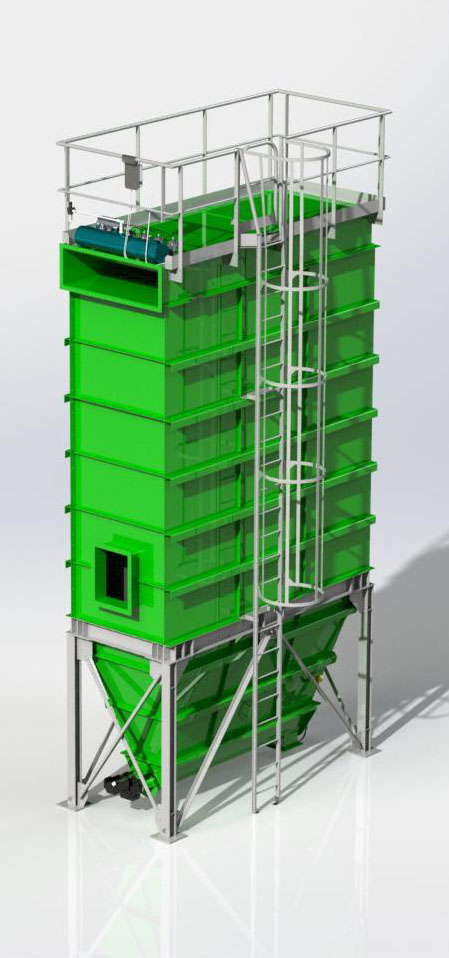

Baghouse dust collector Version silo top type 11

This version without hopper can be installed directly on a silo, without duct connection.

Possibility of two configurations: dusty airflow inlet in the filter or directly in the silo.

Baghouse dust collector Version ATEX

This version is designed to process explosive dusts in accordance with the ATEX directive 2014/34/UE (wood dust, organics, metal, plastic...).

The filter is designed and built to withstand an overpressure of 0.4 bar. It is equipped with one or more vents that protect the filter in the event of an explosion.

Possibility of an interior installation with explosion discharge duct towards the exterior or by replacing the standard explosion vents by ‘’interior’’ vents.

Baghouse dust collector Version high temperature

This version is suitable for processing hot gases at temperatures between 150 and 250°C (with possible peak at 280°C):

- Cleaning system located away from the hot gas flow

- High temperature paint

- High temperature joints

- Viton pneumo-valve membrane

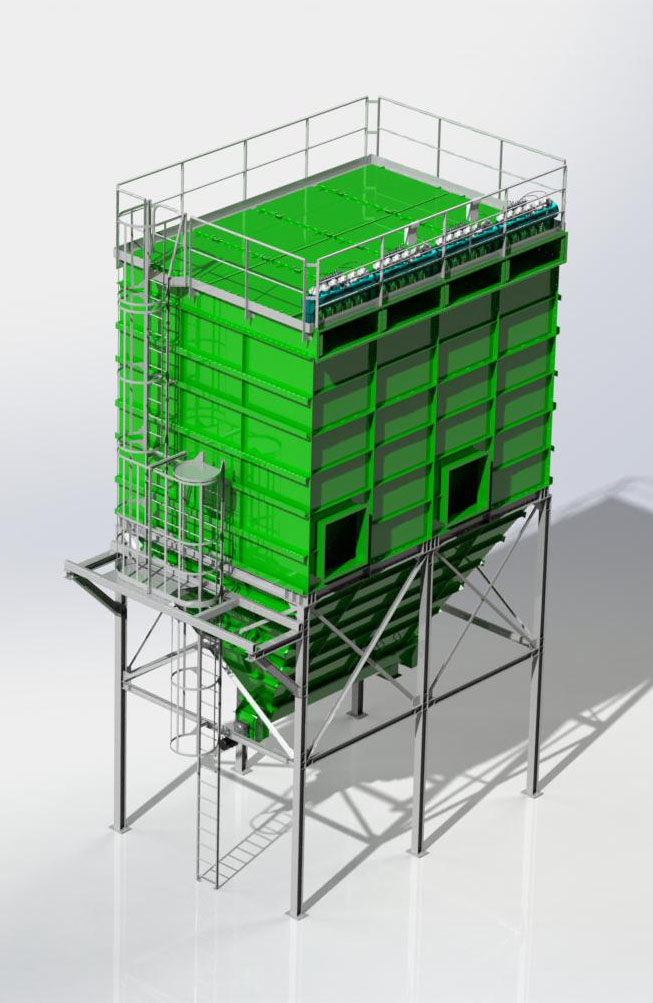

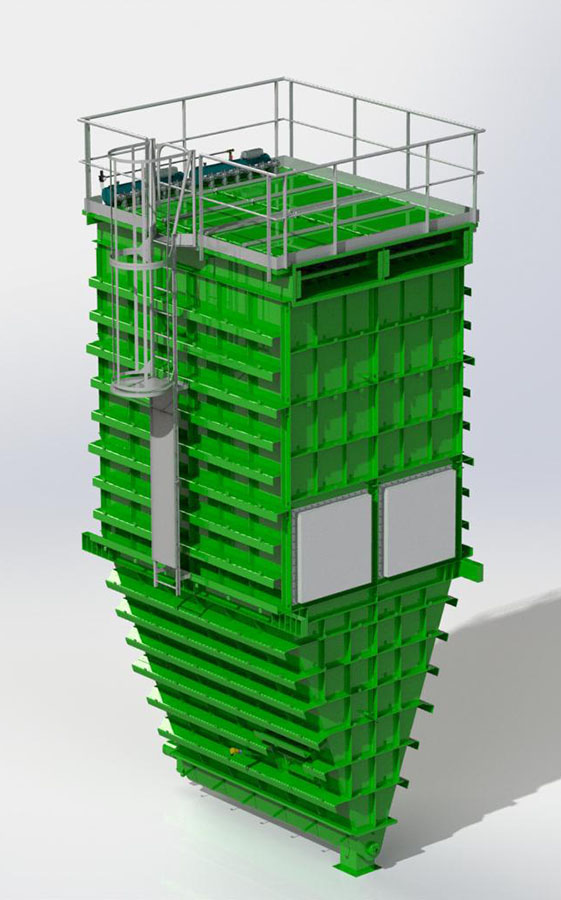

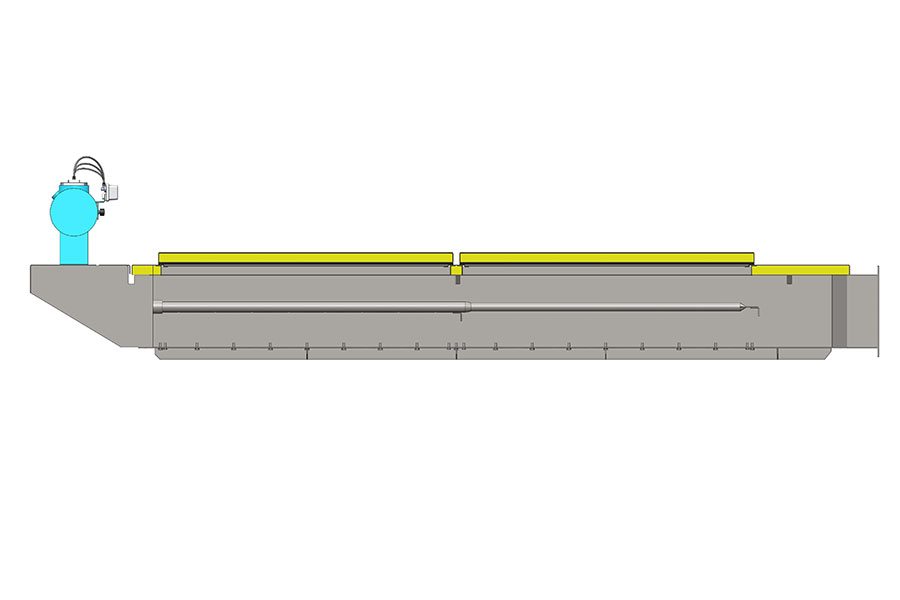

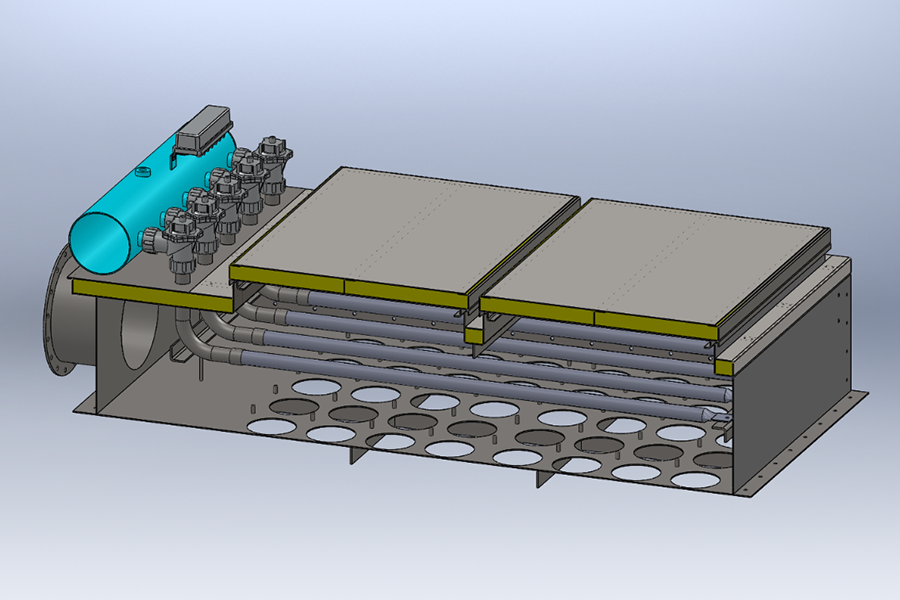

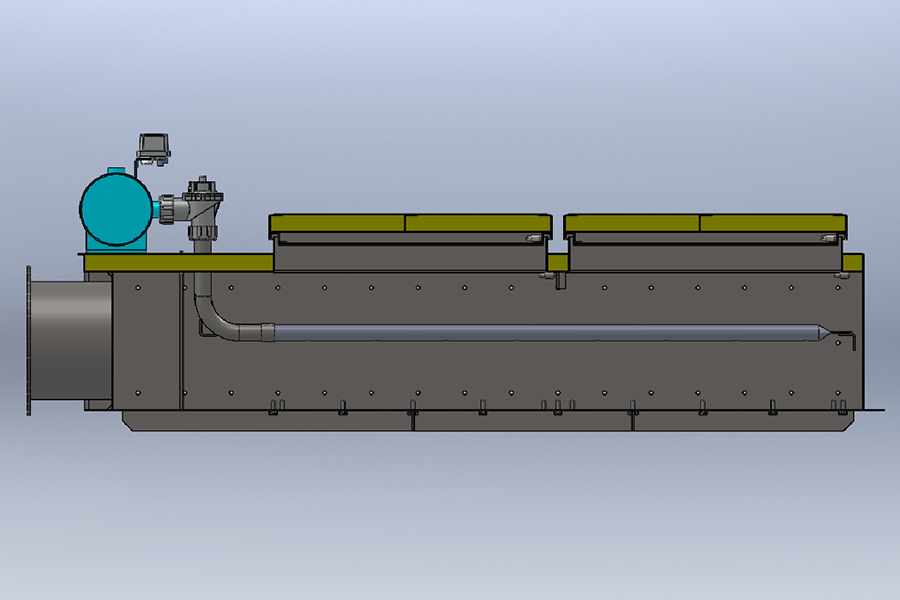

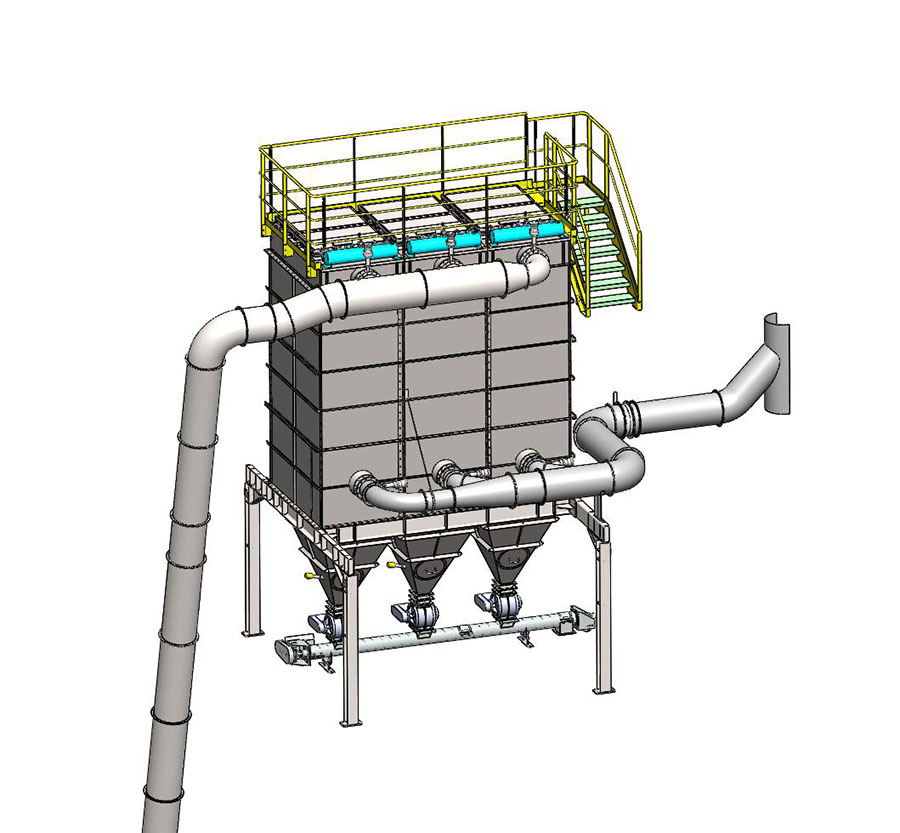

Baghouse dust collector Version Double filter type 20

This version is adapted to very high gas flows (filter surface from 1000 to 3000 m²). It is composed of 2 in-line filters assembled in parallel with a single central dirty air inlet and a single central clean air outlet.

It facilitates installation with a compact filter while reducing inlet and outlet duct need (1 inlet, 1 outlet).

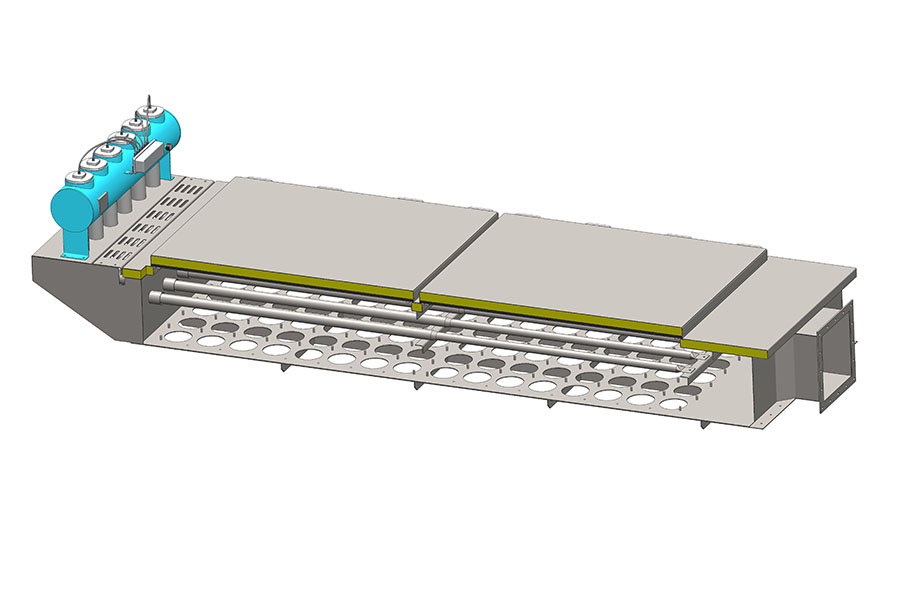

Baghouse dust collector Version off-line or semi off-line

This version can be used for very low bulk density dust with high volatility, most often in high temperature applications.

The principle is to mechanically isolate the inlet and outlet of the compartment which is being cleaned.

Cleaning is then carried out without any flow circulation, which allows even very light dust to pass into the hopper.

Baghouse collector Version off-line

The advantage of partitioning the dirty air side of the compartment :

- no migration of dust towards the neighboring compartment.

- removes the counter-pressure build-up in the system.

Baghouse collector Version semi off-line

Isolation only on the clean air side of the cell being cleaned, without physical partitioning on the dusty air side.

Advantage : efficiency close to the off-line version but more economical (half as many isolation valves, no separation between cells, only 1 hopper or collector).

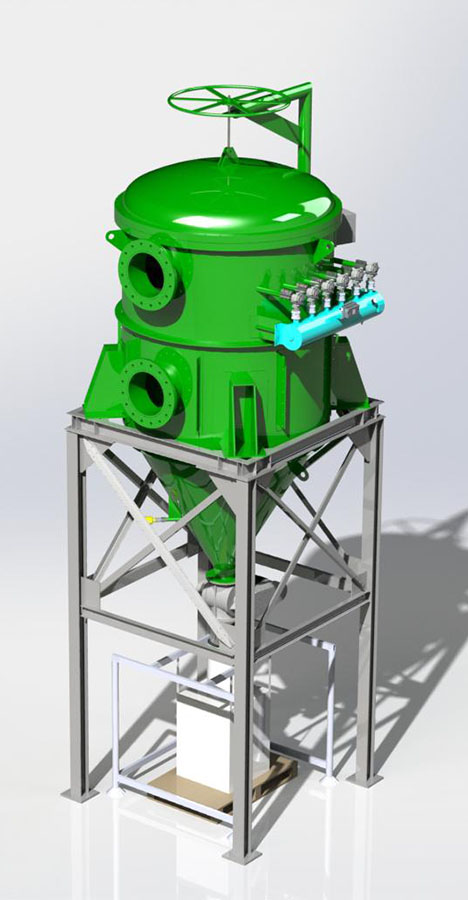

Baghouse dust collector Version circular type 30

Circular baghouse filters are mainly used in the following specific cases:

- Processes in which the operating pressure (negative or positive) exceeds 1000 mmCE (and up to several bars).

- Agri-food, chemical or pharmaceutical industries (easier internal cleaning)

- A specific calculation and manufacture code must be applied (EN13445, EN14460, CODAP, ASME...).

- ATEX version with a resistance pressure (Pred) over 0.4 bar

Can be produced without explosion vent, with a resistance pressure from 10 to 11 bars (resists the maximum dust explosion pressure: Pmax)

Calculation and construction according to standard EN14460: standard relating to explosion-proof devices.

-Type 32 : clean air chamber

-Type 31 : clean air chamber + dirty air chamber

-Type 30 : clean air chamber + dirty air chamber + hopper

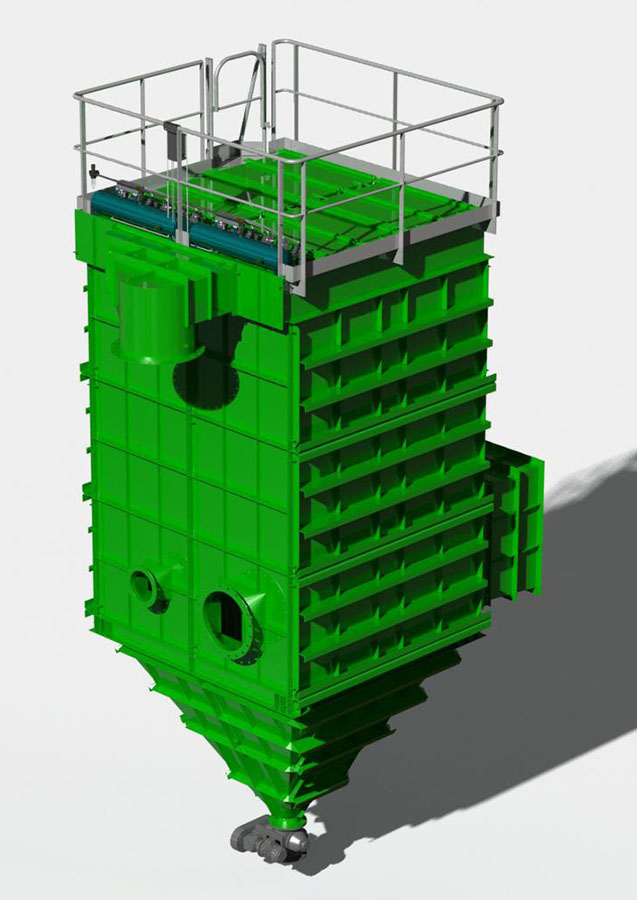

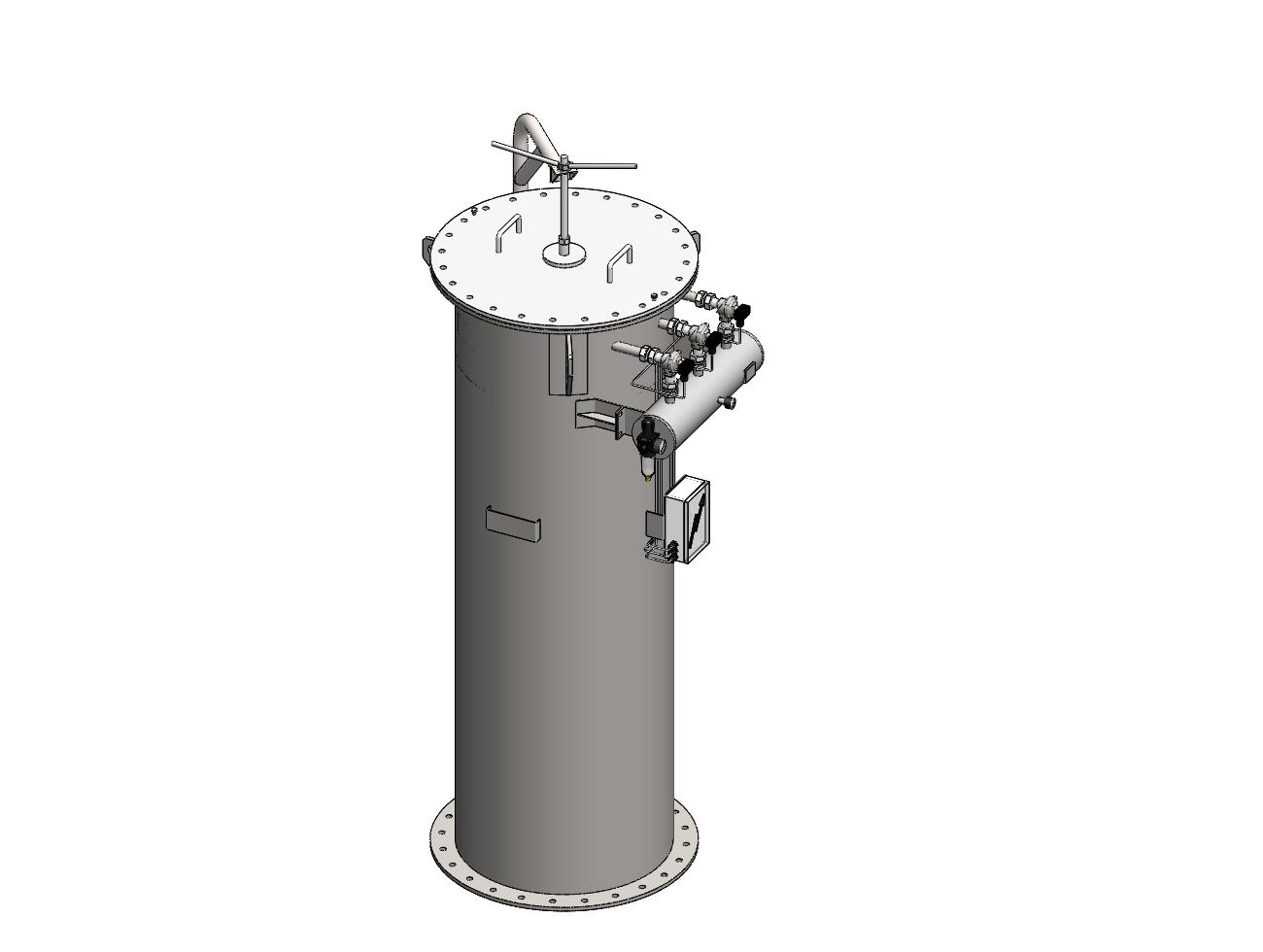

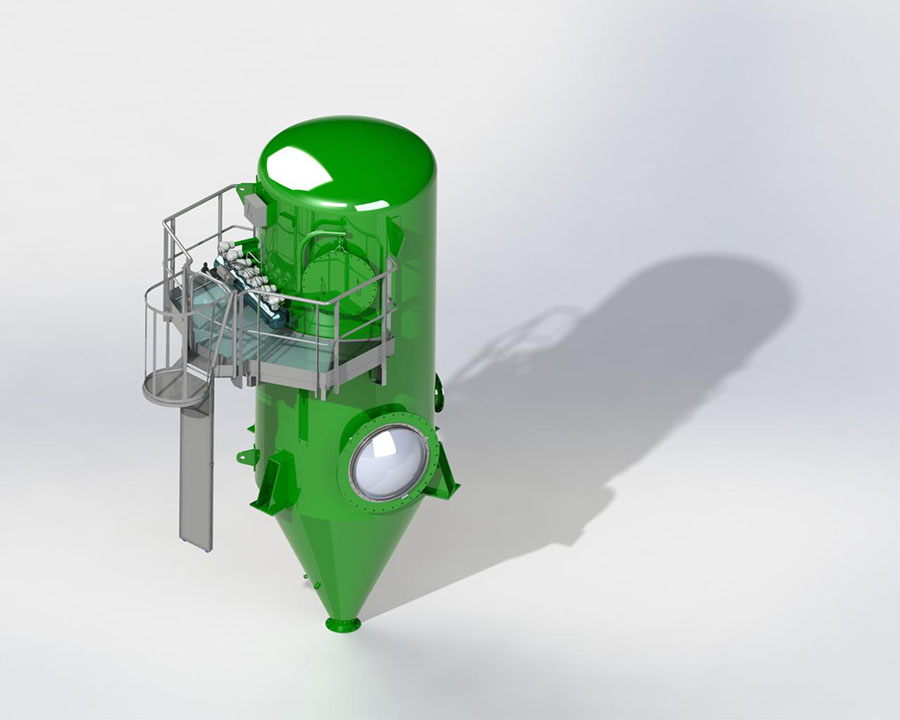

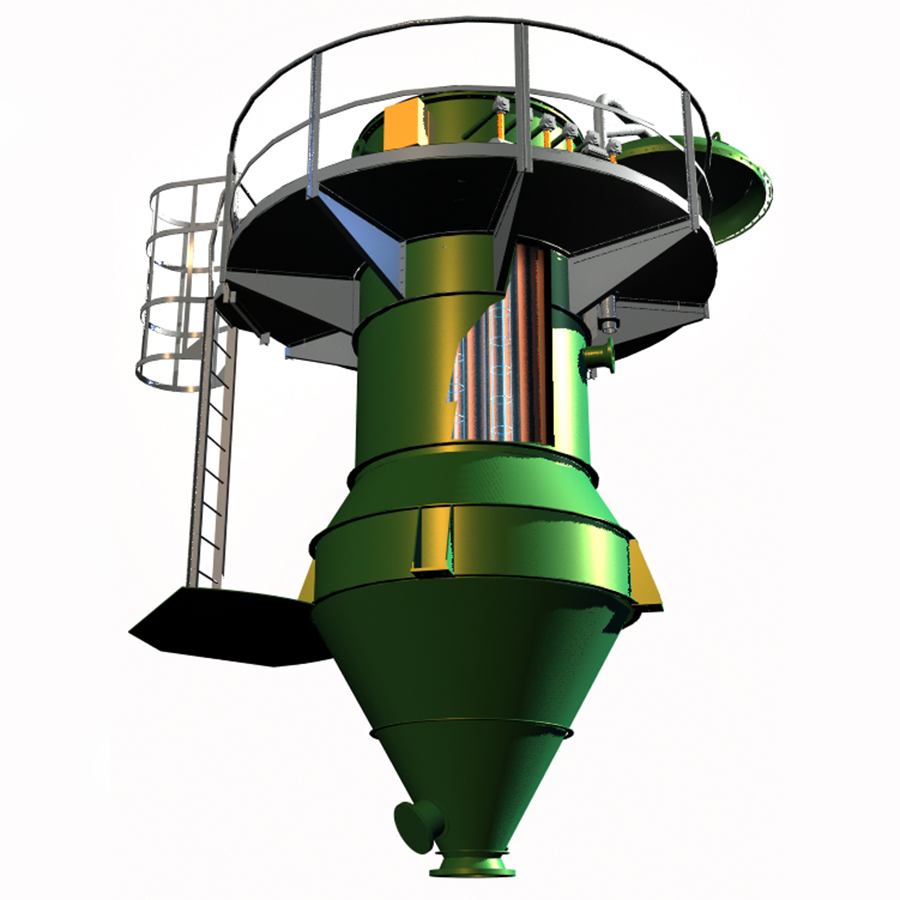

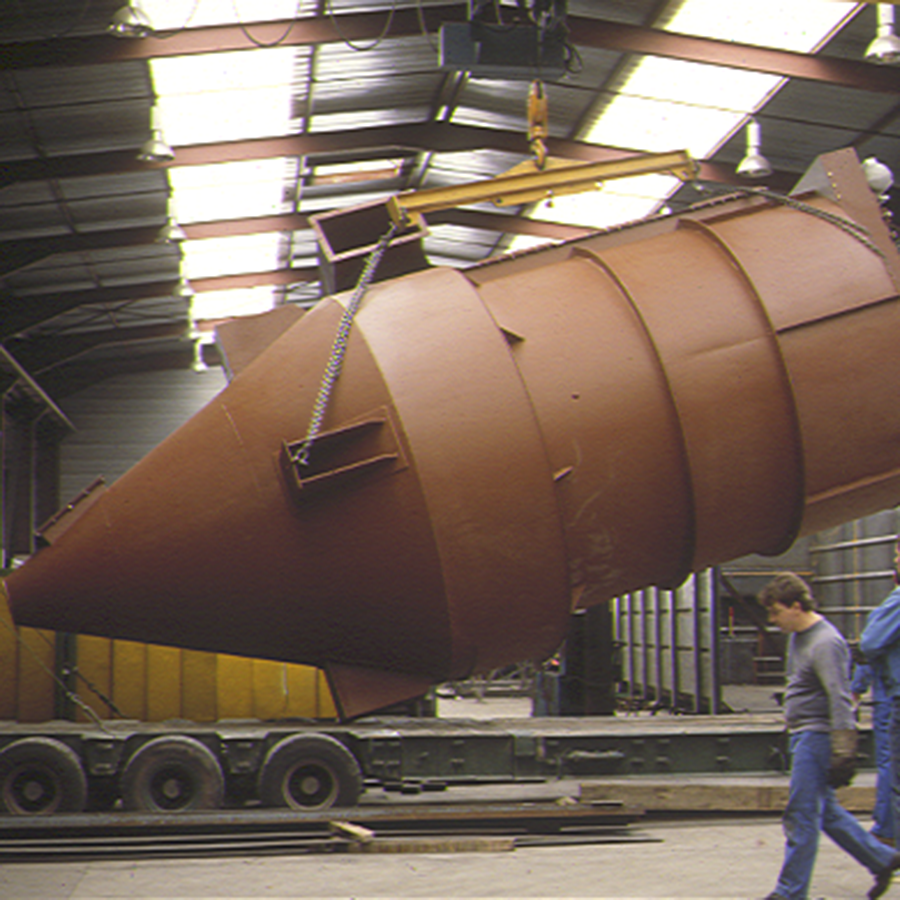

Baghouse dust collector Version Cyclofilter Type 33

The cyclofilter is designed to process gas flows with a high dust content.

It combines the cyclone principle of pre-separation and the filtration efficiency of bag filters in terms of emission.

It features a tangential inlet that enables the bulk of the dust to be carried to the hopper by cyclonic effect without passing through the filter bags.

It can be used in processes where the operating pressure (negative or positive) is very high and in the various scenarios listed for the circular baghouse filter version FP type 30.